Our services

E-booking Warehousing of plastics, rubber, elastomers, paper, phosphates, animal nutrition and ADR9 products. Loading and unloading Bonded warehousing Warehouse storage Silo storage Storage for containers Upgrading Demetallising Homogenising Dedusting Quality control Sieving Transport and distribution Transport in bulk containers Transport in containers Transport in tautliners Logistic services (Re)packing and reconditioning Bagging Customs forms Loading and unloadingHomogenising

A homogenised lot of granules or regrind is essential for smooth feed-in to your or your customers extruders and injection moulding machines. Homogenising plastic granules and regrind is one of our core activities. To maximise quality and efficiency, we focus exclusively on lots between 25 and 125 tonnes, and we use a top-of-the-line Combiflow® blender.

You tell us what you need, and we create a customised blending procedure to achieve your desired specs. We can homogenise your granules and regrind based on material type, colour, MFI, and density.

Homogenising = Adding value = Increasing margin

Homogenising isn’t all that difficult in itself – certainly not when you’ve been doing it for a long time, as we have at Verkooijen. But the combination of ultra-short response time, brainstorming a solution to your specific problem, scheduling the job, executing it, and delivering a spic-and-span result within just a few days – all according to ISO 9001 – is where we stand out from the crowd (if we do say so ourselves). Your major advantage is the value we add through homogenisation. Within just a few days, we transform a problematic lot of plastic granules or regrind from off-spec to near-prime, at a cost that’s just a fraction of its increase in value. The maths speaks for itself.

Blending and homogenising granules and regrind

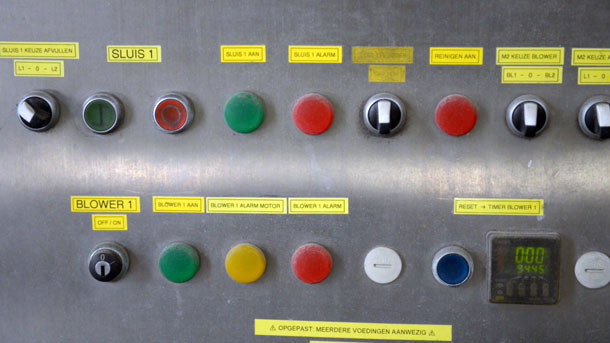

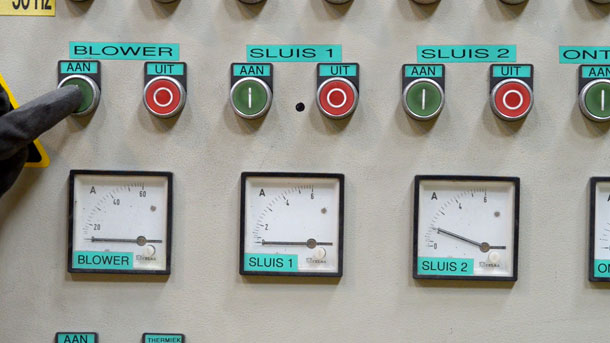

Verkooijen has two blending silos. We blend granules and regrind according to Coperion Waeschleâ Combiflow® principle. Each silo has a capacity of 250 m3. We use completely separate systems – silos, blowers, and sluices – for granules and for regrind.

The temperature of the air entering the blower is fully controlled, independent of the outside temperature. The air is filtered so that 100 percent clean air is pumped into the granules or regrind. That way, we prevent contamination by even the tiniest unwanted particle in the air taken in.

Latest news

Recently we launched e-booking: the button underneath will forward you to our online timelock-reservation system.